Short Lead Time for Concrete Foaming Agent Powder - soap noodle 69% – Standard Imp&exp Detail:

Additional Info

Packaging: 25kg/bag,

Productivity: 500 MT/Month

Brand: std

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 500 MT/Month

HS Code: 34011100

Port: Shanghai,Tianjin

Product Description

soap noodle classification:

According to the source of raw materials can be divided into plant-based soap noodle and animal-based soap noodle; According to the acid-base can be divided into free acid soap noodle and free alkali soap noodle; According to the moisture content can be divided into high moisture soap noodle and low moisture soap noodle; According to the handling of raw materials and the current status of the domestic can be divided into neutralizing soap noodle and cauldron boil soap noodle .

The high temperature and pressure continuous hydrolysis of the feedstock to obtain fatty acids, different fatty acids according to a certain ratio and then with the caustic soda and neutralization reaction was soap base soap vacuum drying, squeezing into soap tablets by a refiner, this method Production of soap tablets better quality, color, smell and stability are better than soap pan soap cooker, the representative of the oil companies benefit the sea;

Vegetable oil or animal oil through the cauldron soap saponification reaction to get a soap base, water and glycerol, the soap base was washed with water, salting out and other operations, the vacuum drying can be produced into soap tablets; soap production process of this method Will produce more wastewater and other waste, higher energy consumption, product quality is slightly worse, especially in the production of high-quality soap tablets, the more vulnerable, has been phased out.

Soap noodle

Mainly used in the production of soap, laundry soap, transparent soap, soap powder used in Washing Powder and other soap products.

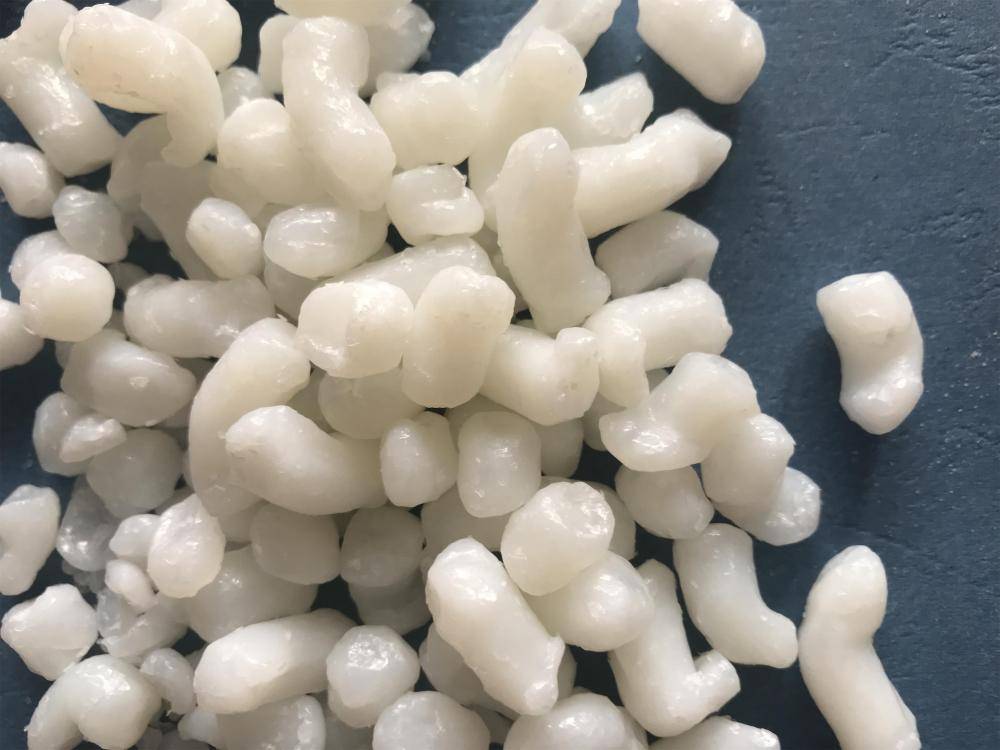

Basic traits Appearance: white granular solid (most vegetable oil soap particles) Milk yellow granular solid (animal-based soap)

I produced the soap noodle are divided into five processes. The first is with oil, according to the formula of palm oil, beef and mutton, coconut oil and other oil mixed; with a good mixture of fat sent to the hydrolysis tower, and water reaction, to obtain crude fatty acids; crude fatty acids after distillation finished fatty acids; finished Continuous neutralization of fatty acids gives a soap base; the soap base is reconciled and dried in vacuo to give soap tablets.

Soap noodle specification:

|

Type |

fatty acid |

Free alkali(NaOH) |

Free acid(oleic acid) |

Chloride (NaCl) |

Moisture &volatile |

Glycerin |

Freezing point ℃ |

|

For laundry soap |

55% min |

0.2% max |

—- |

0.7% |

—- |

1% max |

39-43 |

|

60 %min |

0.2% max |

—- |

0.7% |

27% |

2.5% max |

39-43 |

|

|

65 %min |

0.2% max |

—- |

0.7% |

25% |

3% max |

39-43 |

|

|

69 %min |

0.2% max |

—- |

0.7% |

23% |

1% max |

39-43 |

|

|

For hand soap |

72% min |

—- |

0.8% max |

0.7% |

20% |

1% max |

42-46 |

|

74 %min |

—- |

0.8% max |

0.7% |

18% |

1% max |

40-46 |

|

|

75 %min |

—- |

0.8% max |

0.2-0.6% |

17% |

1% max |

43-47 |

|

|

78 %min |

—- |

0.1-0.8% |

0.7% |

14% |

1% max |

40-46 |

|

|

80% min |

—- |

0.8% max |

0.2-0.6% |

12% |

1% max |

43-49 |

Looking for ideal Soap Noodle for Chloth Soap Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the High Fatty Acid Low Moisture Soap Noodle are quality guaranteed. We are China Origin Factory of Soap Noodle for Chloth Soap. If you have any question, please feel free to contact us.

Product Categories : Detergent

Product detail pictures:

Related Product Guide:

The Most Splendid Housing Bubbles in America | Expansive Mortar For Exporting

Asia Pacific Data Protection and Cyber Security Guide 2018 – Shifting landscapes across the Asia-Pacific region | Hogan Lovells | Hsca Demolition Agent

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for Short Lead Time for Concrete Foaming Agent Powder - soap noodle 69% – Standard Imp&exp, The product will supply to all over the world, such as: Manchester, Algeria, Jamaica, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

-

Hot sale Factory Super Quality Expandable Expan...

-

Factory directly supply 99% Bv Approved Quality...

-

Factory wholesale Quality Cooking Msg Monosodiu...

-

China Gold Supplier for 44.5% Magnesium Chlorid...

-

8 Year Exporter 99%msg For Restaurant - Discou...

-

China Cheap price Magnesium Chloride Anhydrous ...